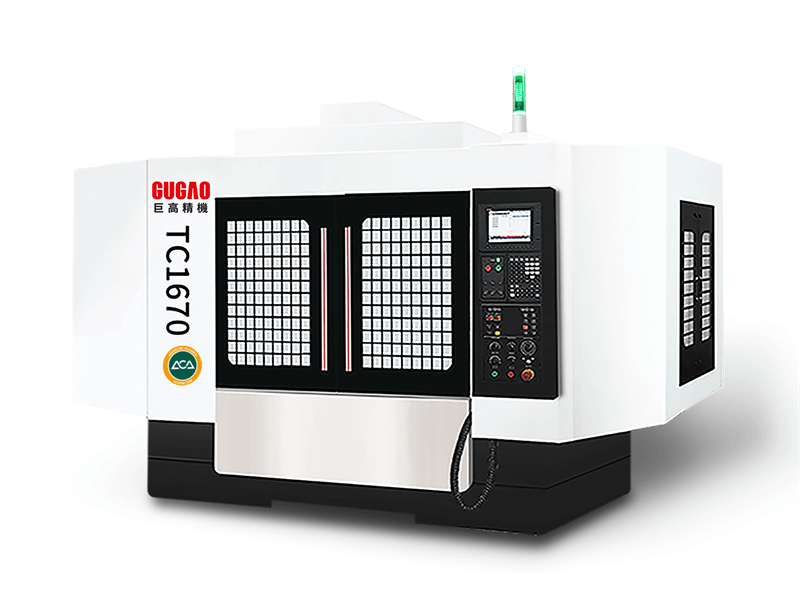

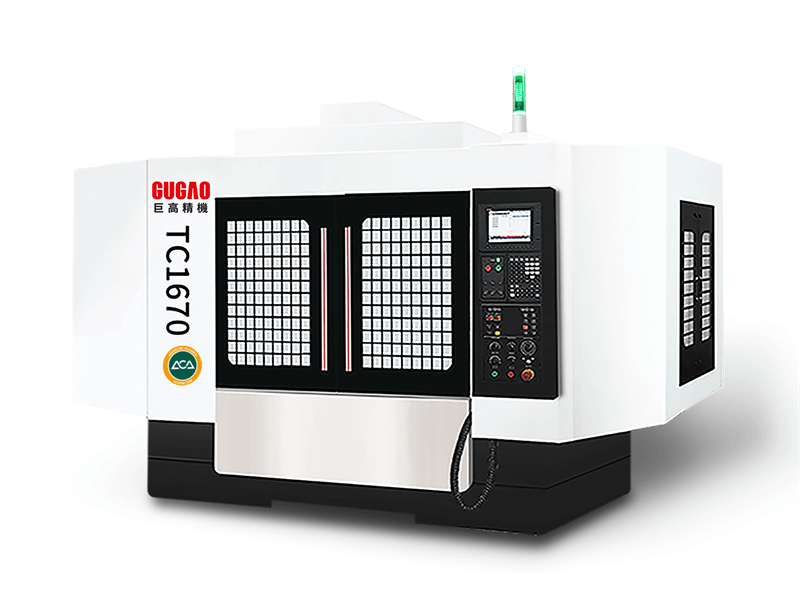

- 1700*600 Worktable

- Axes rapids 30*36*48 m/min

- Extra-large span base

- High-speed & powerful spindle

- Extensive application fields

| Name | Parameter |

| Travel | |

| Three axis travel | 1600/700/400mm |

| Distance from spindle end face to worktable center | 150-450 mm |

| Worktable | |

| Worktable Size(L*W) | 1700×650 |

| Maximum load-bearing capacity | 500kg |

| T-shaped slot (quantity × width× spacing) | 5×14×130 mm |

| Spindle | |

| Spindle diameter Spindle bore taper | φ100/ BBT30 |

| Max spindle speed | 20000 rpm |

| Motor power | 3.7/5.5 kW |

| Feed | |

| Three axis fast moving speed (X/Y/Z) | 30/36/48 m/min |

| Three axis feed speed (X/Y/Z) | 10/10/10 m/min |

| Tool Magazine | |

| Magazine capacity | 21 |

| Max tool diameter/length/weight | φ60mm/200mm/3kg |

| Maximum tool diameter (full tool/adjacent empty tool) | 60/80 mm |

| Tool exchange time (T-T) | 1.3s |

| Accuracy | |

| (X/Y/Z) Positioning accuracy | 0.012 mm |

| (X/Y/Z) repositioning accuracy | 0.008 mm |

| Others | |

| Linear guide rail specifications (X/Y/Z) | Ball 35/35/45 mm |

| Ball screw specifications (X/Y/Z) | 40/32/36 mm |

| Servo motor specifications (X/Y/Z) | 13.7/13.7/22.5 Nm |

| Air source/pressure | 280L/min 6~8bar |

| Total electrical capacity | 15kVA |

| Machine size (X×Y×Z) | 4000×3400×3100 mm |

| Estimated weight | 6200 kg |

| Standrad Accessories | Optional accessories |

| 1. FANUC 0i MF CNC | Oil Mist Collector |

| 2. Hand held operation unit | Oil skimmer (Electric) |

| 3. Clamp-arm tool magazine | Safety Door Grating |

| 4. Automatic lubrication system | Automatic Safety Door |

| 5. Three-color light | Wireless Handwheel |

| 6. Air curtain protection | Electric Cabinet AC |

| 7. Spindle air blowing device | Simple Spindle Ring Spray |

| 8. Working light | 4 Axis Rotation Table |

| 9. Relevant accessories | 5 Axis Rotation Table |

| 10. Set of standard technical documents | Tool Magazine Inverter |