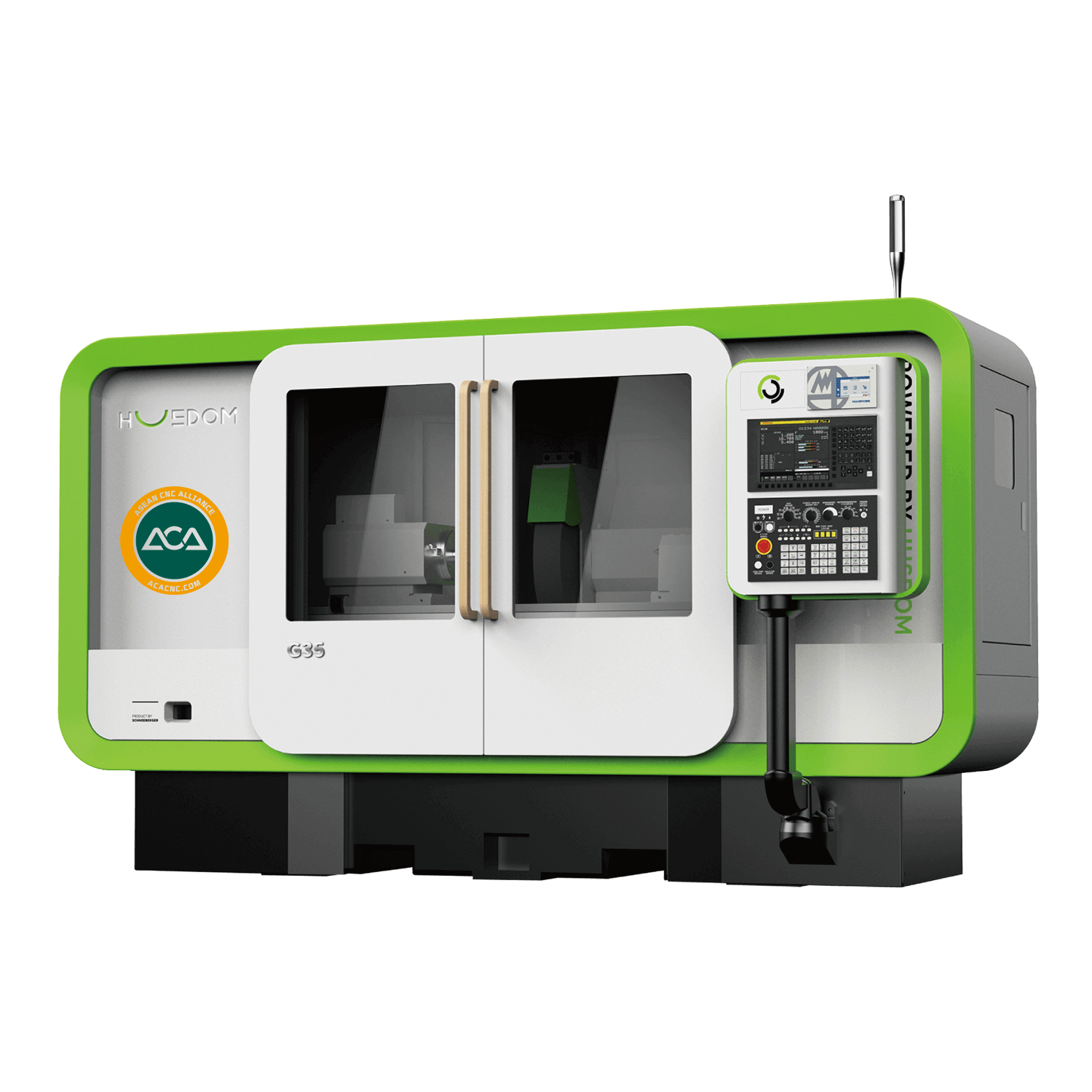

- Max. 350mm of Workpiece Swing Diameter

- Max. 1000mm of Grinding Length

- SCHNEEBERGER mineral casting

- 0.003mm of Processing Accuracy

- Fully Enclosed Metal Cover

| G35-100 | |

| Specifications | |

| Swing diameter | 350mm |

| Max. Grinding diameter | 330mm |

| Max. Grinding length | 1000mm |

| Distance between centers | 1050mm |

| Max. Weight of workpiece between centers | 200kg |

| Grinding wheel head | |

| Grinding wheel dimensions | |

| (Outer* inner* thickness) | 510*(25~100)*203.2/ optional 510*(25~100)*203.2 |

| Spindle motor power | 7.5 (Optional 11) Kw |

| Cutting line speed of grinding wheel | 60m/s (Optional 100m/s) |

| Spindle axis size | 67 mm |

| Spindle bearing type | Bearing type spindle(high-speed electric spindle optional) |

| Workhead | |

| Type | Dead center/ Movable center |

| Center taper | MT5 |

| Spindle speed | 10~1000rpm |

| Motor power | 2.5 Kw/hp |

| Tailstock | |

| Center taper | MT4 |

| Sleeve diameter | 58mm |

| Spindle travel | 35mm |

| X-axis grinding wheel slide | |

| Table travel | 400mm |

| Quick feed speed | 16M/min |

| Min.feed/every scale | 0.001/0.01/0.10mm |

| Feed mode of grinding wheel | Plunge/Angular |

| X-axis servo motor | 2.2 Kw |

| Grinding wheel slide | A-V-flat structure guide rail |

| Z-axis grinding wheel slide | |

| Table travel | 1300mm |

| Quick feed speed | 16 M/min |

| Min.feed/every scale | 0.001/0.01/0.10mm |

| Z-axis servo motor | 2.2 Kw |

| Table slide | A-V flat structure guide rail |

| Bench rotation angle | 4 degrees of clockwise rotation/9 degrees of counterclockwise rotation |

| Universal | |

| Grinding wheel head lubricating oil pump | 1/4HP |

| Grinding fluid pump | 1/4HP |

| Guide oil pump | 25w/HP |

| Grinding wheel head oil tank capacity | 30L |

| Grinding fluid tank capacity | 120L |

| Guide oil tank capacity | 8L(with full-time lubrication) |

| Net weight | 6200kg |

| Dimensions | 3200L*2500W*1900H mm |

| l Bed lubrication device |

| l FANUC Controller system |

| l Roller dresser device |

| l Grinding wheel balance rod and balance stand |

| l Grinding wheel guard |

| l Foot pads and screws |

| l Flange, puller, and center ejector rod |

| l Cutting fluid (paper belt and magnetic filter) |

| l Work light |

| l Hand tools and toolbox |

| l Standard grinding wheel (510/50/152.4) |

| l Full enclosure sheet metal |

| l Spindle lubrication device |

| l Hydraulic device |

| l Pneumatic unit |

| l Manual and accuracy inspection report |

| l 60m grinding wheel spindle constant line speed |

| l Ball screw (C1 grade Hiwin or Yintai) |

| l Servo motor (Japan FANUC Bis22-2000) |

| l Workhead motor (Taiwan Delta) |

| l Outer diameter measurement (Italy Marposs) |

| l Spindle constant temperature air conditioner (China Tongfei) |

| Optional Standard: (Charge in Additionally) |

| l Roller grinding base |

| l Forming roller |

| l Cutting oil constant temperature air conditioner |

| l Optical scale (Fagor, HEIDENHAIN) |

| l Oil mist recovery machine |

| Special Items: |

| Voltage:380V50HZ |