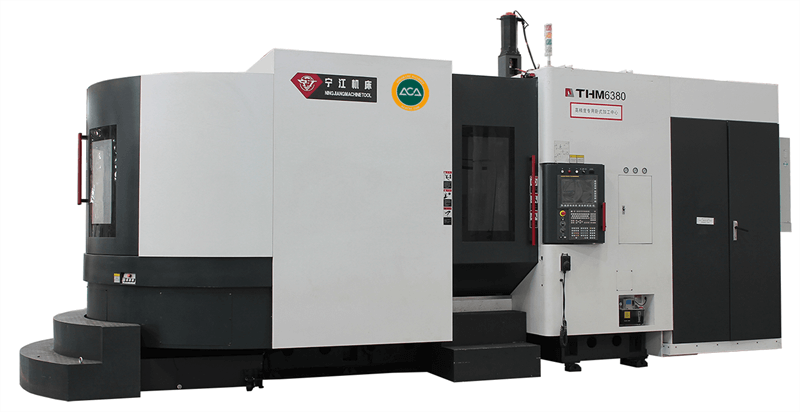

- More ergonomic design

- Linear drive system ensures high-precision

- T-Type integrated frame structure for the column

- Imported multi-row high-precision combination bearings

| Items | Parameters |

| Pallet worktable | |

| Worktable Surface (L*W) | 800*800mm |

| B-axis inde | 1°*360(End tooth pallte)/0.001°*360000(Continuous) |

| Worktable rpm | 10 r/min |

| Pallet loading capacity(Dual table) | 2000kg |

| Max. dia of workpiece | Φ1250mm |

| Number of change pallets | 2 |

| Pallet Change time | 20 |

| Travel | |

| X-axis (Corlumn) | 1300mm |

| Y-axis (Headstock) | 1000/1200 mm |

| Z-axis(Worktable) | 1100mm |

| Spindle center to pallet surface | 50~1050/1250mm |

| Spindle nose to pallet center | 200~1300mm |

| Spindle | |

| Spindle Taper | No.50 |

| Spindle rpm | 20~5000 r/min(Optional 20~8000r/min) |

| Speed Selection | Programmable in the full range |

| Spindle motor | 30/37 kW |

| Max. Spindle torque | 307/1288 Nm(Add reducer) |

| Tool magazine | |

| Tool pockets | 40(optional 60, 80, 120) |

| Type of tool shank | BT50 (Optional ISO50, SK50, JT50) |

| Max. tool diameter |

Φ125(With tool at adjacent pocket)/ Φ250mm without tool at adjacent pocket) |

| Max. tool length | 550 mm |

| Max. Individual tool weight | 25kg |

| Tool change time (T to T) | 4.5 s |

| Tool selection | Fixed tool station/Bi-derectional |

| Driven for controllable axes | |

| Feedrate | 0~20 m/min |

| Rapid travel (X, Y, Z) | 40 m/min |

| Servo motor (X, Y, Z) | 6 kW |

| B-axis servo motor | 3/4 kW |

| Location feedback (X, Y, Z, B axis) | Encoder |

| Min. Increment | 0.001 mm (Option 0.0001) |

| Min. Increment | 0.001 mm (Option 0.0001) |

| Machine Accuracy | |

| Positioning accurac (X, Y, Z) |

THM6380: 0.008mm TH6380; 0.015mm |

| Repeatability |

THM6380: 0.004mm TH6380: 0.008mm |

| B-axis indexing |

THM6380: 8'' Th6380: 8'' |

| B-axis indexing repeatability |

THM6380: 4'' Th6380: 4'' |

| Geometric accuracy standard |

Precision Level: GB/T 20957.1-2007 Standard Level: GB/T 18400.1-2010 |

| Installation Specification | |

| Machine net weight | 24 T |

| Tool power consurmption | 100KVA |

| Power supply | 380 V/ 50Hz/Tri-phase |

| Air pressure | 0.6 Mpa |

| Air flow-rate | 350L/mm |

| Standard Accessories | Optional Accessories |

| Main machine | Squirt gun |

| Full closed machine cover | Manual bolwing gun |

| Work lamp | Tool probe |

| Tri-color lamp | Workpiece probe |

| Chip remover | Rotary Windows |

| Tool cooling system | Spindle center cooling |

| Self-diagnosable system | |

| ATC cover | |

| Pallet positioning hole blowing device | |

| Spindle hole blowing device | |

| Manual pulse generator | |

| Self power brake system | |

| Manual tool change device(Tool magazine) | |

| Manual tool change device(Spindle) | |

| Automatic Lubrication system | |

| Pallet cleaning device | |

| Chain-type chip remover and carrier | |

| Coolant degreasing device |