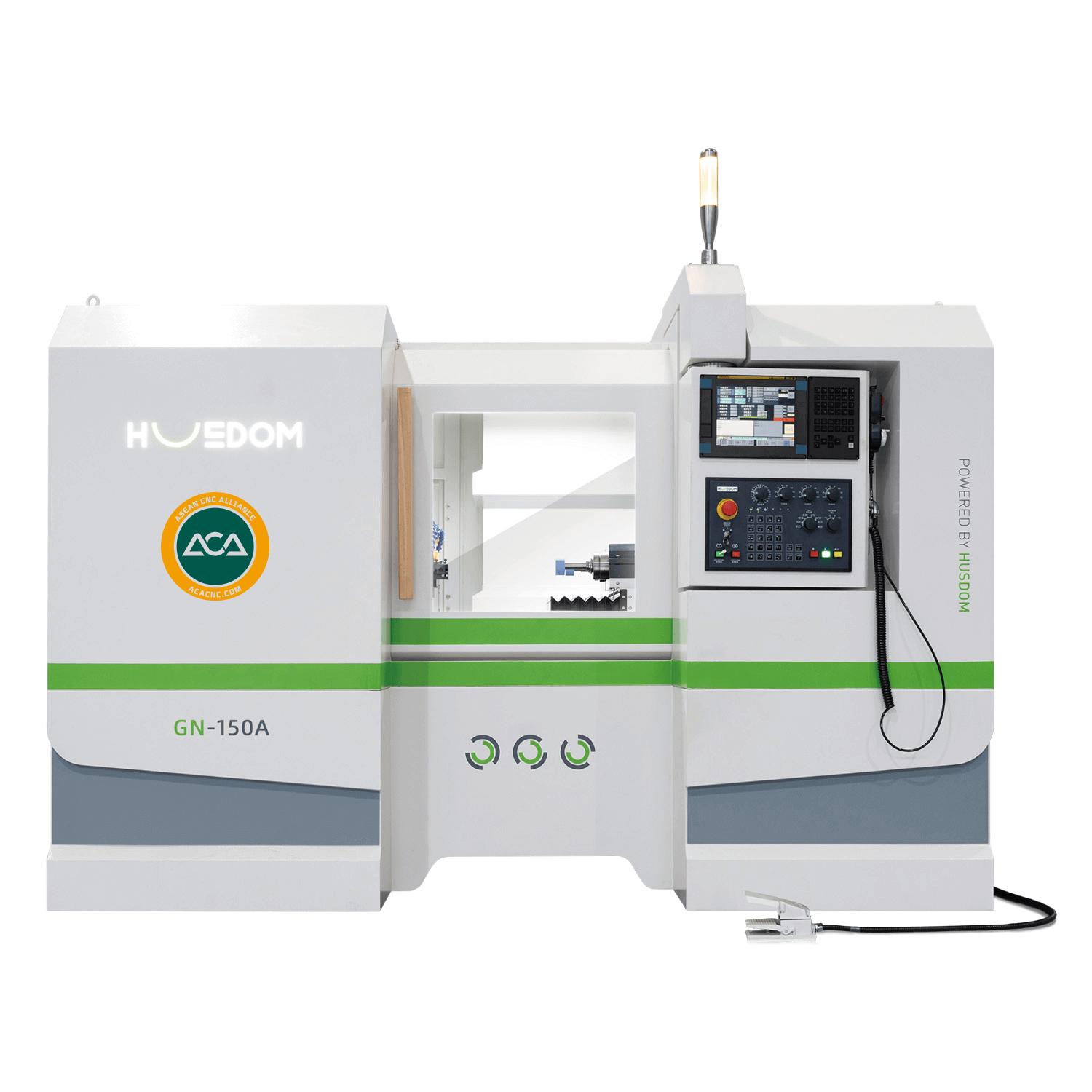

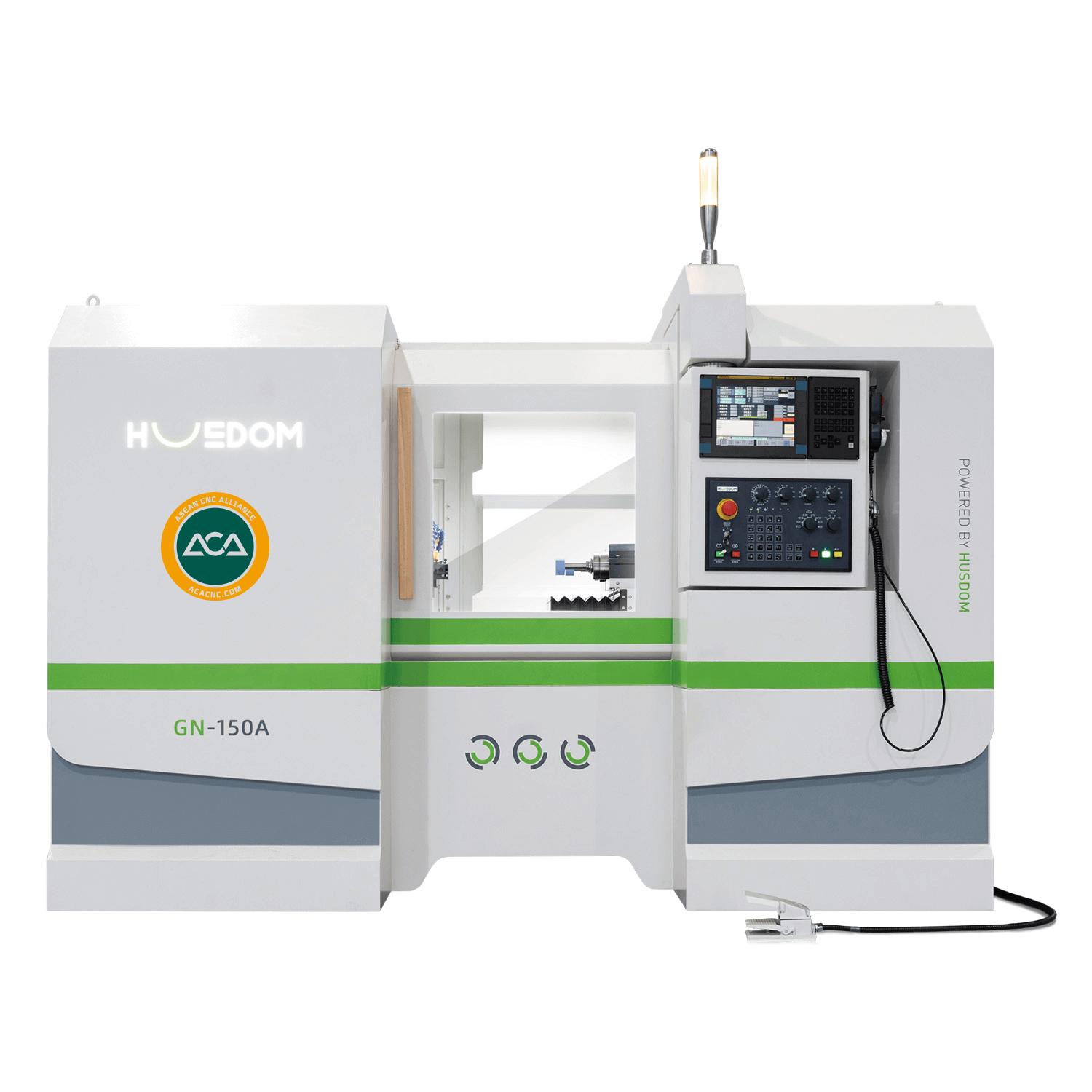

- Max, Grinding Depth of 150mm

- FANUC System & Unique Interface

- Processing Accuracy of 0.003mm

- High-Quality and Stable Base

- Semi-Enclosed Shield

| GN-150A | |

| Processing capacity | |

| Range of grinding diameter | 4~320mm |

| Max. Grinding depth | 200mm |

| Max. swing diameter of workpiece | 435mm |

| Inner swing diameter of waterproof cover | 400mm |

| Control System | |

| Controller | FANUC/0i-TF |

| Work Head | |

| Spindle speed | 0~1000rpm |

| X-axis feed rate/ Max. travel | 10M/min/350mm |

| Min. displayed unit of X-axis | 0.0001mm |

| Rotation angle of working head | -5 °~+15° |

| Table | |

| Feed rate of Z axis | 10M/min |

| Max. travel of Z axis | 345+200mm |

| Min. displayed unit of Z-axis | 0.0001mm |

| Height of working spindle center from ground | 1100mm |

| Oil pressure system | |

| Oil tank capacity | 30L |

| Cooling System | |

| Cutting fluid tank capacity | 260L |

| Drive motor | |

| Oil pressure motor | 0.75Kw(1HP) |

| Cutting fluid motor | 0.18Kw(1/4 HP) |

| X-,Y- and Z-axis servo motor | X:1.2 Kw/Y:1.6 Kw/Z:1.2Kw |

| Grinding wheel motor(Kw) | 4HP |

| Spindle head motor | 2.2·4P(3HP) |

| Others | |

| Automatic oiling machine | 4L |

| Dimensions(L*W*H) | 3500*2150*2200 mm |

| Weight | 5500kg |

| Configuration: |

| 1.1 Full-coverage guard |

| 1.2 Electrical cabinet heat exchanger |

| 1.3 Automatic lubrication system |

| 1.4 Magnetic filter + water tank |

| 1.5 Work light, three-color warning light |

| 1.6 Foundation bolts and machine leveling pads |

| 1.7 Tool box and tools |

| 1.8 Spindle coolant spray |

| 1.9 Machine, electrical, and operation manuals |

| 1.10 2 diamond pens (single-point) |

| 1.11 Transformer with voltage stabilization |

| 1.12 10m power cable |

| Optional Equipment: |

| 2.1 Oil mist recovery unit |

| 2.2 Oil-water separator |

| 2.3 Power dressing system (including metal grinding wheel) |

| 2.4 Water tank temperature control device |

| 2.5 X and Z-axis optical scales (Fagor or Heidenhain) |