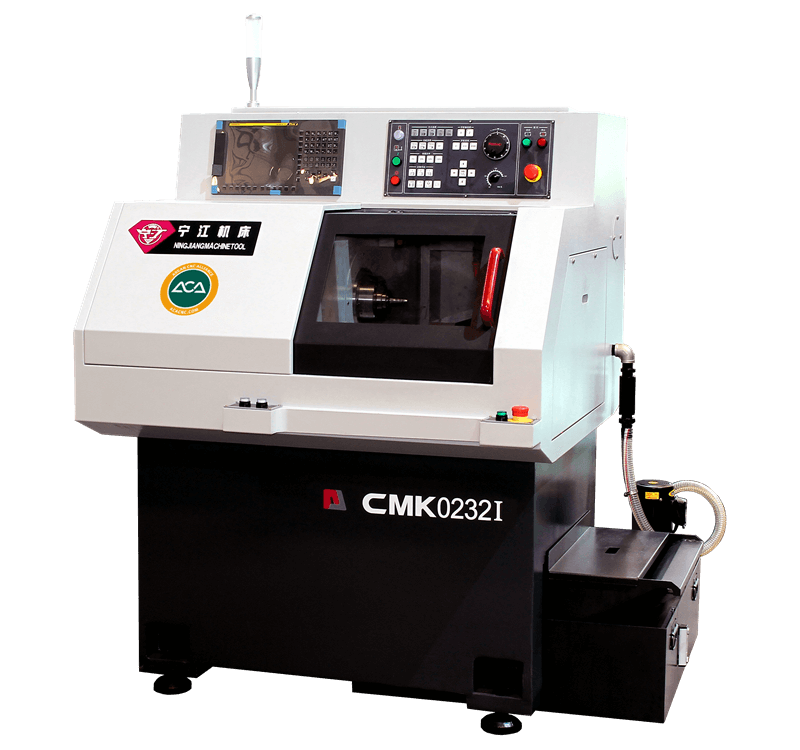

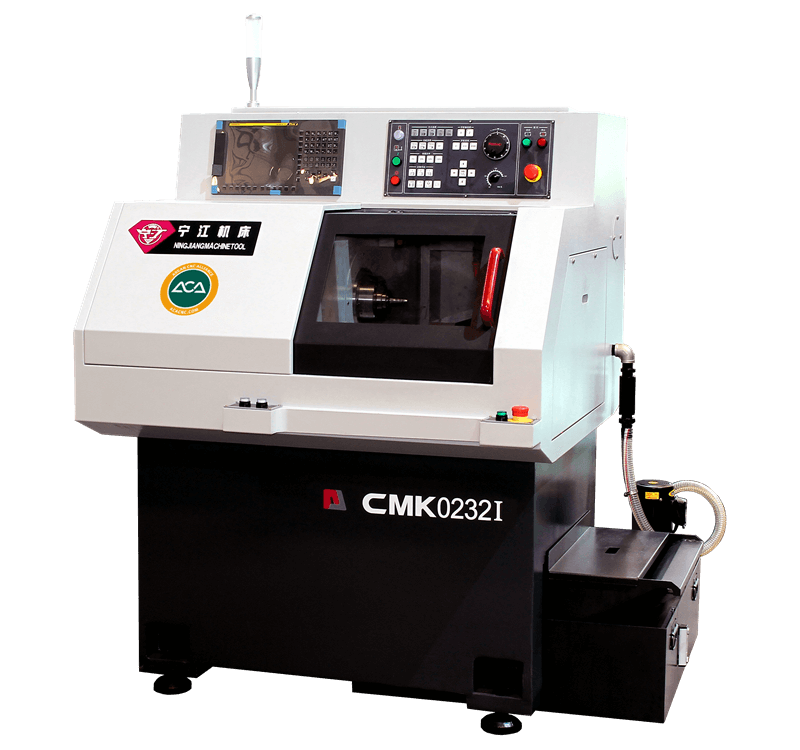

High-Precision CNC Lathe: Equipped with FANUC Series 0i-TF Plus CNC system, ideal for precise machining of short shafts, disc-type, and small parts.

Wide Application: Suitable for various industries including IT, electronics, telecommunications, refrigeration, home appliances, aerospace, automotive, and more.

Compact Design: Space-saving with a compact structure, suitable for diverse work environments.

User-Friendly Operation: Easy to operate with an attractive design, offering a user-friendly experience.

| Specification CMK0220II | |

| CNC System: Standard | FANUC, Optional: Syntec |

| Machining Range: | |

| Maximum Bar Diameter: | φ32 mm |

| Maximum Machining Diameter: | φ100 mm |

| Maximum Workpiece Length: | 100 mm |

| Maximum Swing Diameter: | φ300 mm |

| Swing Diameter Over Tool Post Base: φ120 mm | φ120 mm |

| Spindle: | |

| Maximum Spindle Speed: | 6000 rpm |

| Spindle Through Hole Diameter: | Φ33 mm |

| Spindle Motor Power: | 3.7/5.5 kW |

| Radial Runout of Spindle Location Hole: | 0.002 mm |

| C-Axis Increment(Servo Spindle): | 0.001° |

| Tooling: | |

| Tool Holder Size for Turning Tools: | 16×80~100 mm |

| Others: | |

| X-Axis Travel: | 320 mm |

| Z-Axis Travel: | 180 mm |

| Precision and Performance: | |

| Single-Row Repeated Positioning Accuracy: | 0.002 mm |

| Rapid Feed Rate: | 24 m/min |

| Feed Motor Power: | 0.75 kW |

| Minimum Increment for Linear Axes: | 0.0001 mm |

| Coolant Pump Motor Power: | 0.37 kW |

| Lubrication Pump Motor Power: | 4 W |

| Additional Specifications: | |

| Coolant Tank Capacity: | 200 L |

| Power Input Capacity: | 6 kVA |

| Air Source Pressure and Flow Rate: | 0.5 MPa, 300 Nl/min (maximum) |

| Machine Weight: | ~1200 kg |

| Machine Dimensions (L×W×H): | 1250 × 1245 × 1580 mm |

| Standard Accessories | |||

| Serial Number | Name | Quantity per Unit | Remarks |

| 1 | FANUC CNC System | 1 | |

| 2 | Nameplates | 1 | Various warning labels, machine nameplate |

| 3 | Transformer | 1 | |

| 4 | Pneumatic System | 1 | |

| 5 | Cooling System | 1 | |

| 6 | Lubrication System | 1 | |

| 7 | Tool Holder | □16 | Includes 4 sets of external tool holders |

| 8 | LED Lighting | 1 | |

| 9 | Machine Three-Color Alarm Light | 1 | |

| Optional Accessories | |||

| Serial Number | Name | Remarks | |

| 1 | Automatic Loader | Automatically feeds material; switches to the next bar when one is used up. | |

| 2 | Radial Power Tools | Various power tools available to meet different processing needs. | |

| Axial Power Tools | |||

| Vertical Power Tools | |||

| 3 | Chucks | 1) Solid or hollow pneumatic chucks | |

| 2) Solid or hollow hydraulic chucks | |||

| 3) Manual chucks | |||

| 4 | Ejector | Automatically feeds material | |

| 5 | Chip Conveyor | Automatically collects chips during processing | |

| 6 | Flying Cutter Mechanism | Used to process workpieces into quadrilateral or hexagonal shapes | |

| 7 | High-Pressure Internal Cooling System for Tools | Improves cooling and chip removal efficiency for difficult-to-machine parts. Typically available in 70 Pa, 100 Pa options. | |

| 8 | Parts Conveyor Belt | ||

| 9 | Spindle Internal Cooling System | Optional based on different usage environments and requirements. |