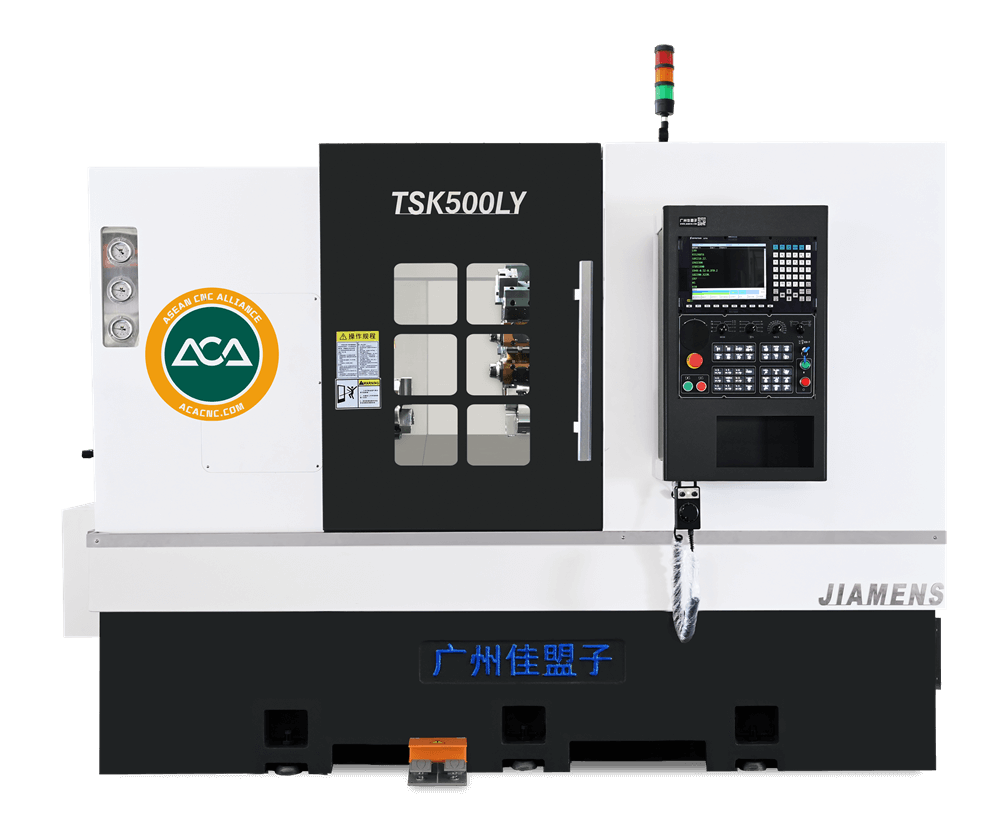

- Max. Turning Length 360mm

- Spindle Bore Dia.66mm

- 30-degree slant bed saddle structure

- Equipped with reinforced P3-class ball screws

- Z-axis adopts a configuration with six sliders

- Equipped with a hardened Y-axis power turret

| Name | Parameter |

| Maximum Turning Diameter (Bed) | 700 mm |

| Maximum Processing Diameter (Disc) | Φ330 mm |

| Maximum Turning Diameter Over the Carriage | Φ450mm |

| Maximum Workpiece Length | 490mm |

| Maximum Bar Through-hole Diameter | Φ52 mm |

| Distance between spindle chuck end faces | 90-640 mm |

| X-axis Effective Travel | 210mm |

| Z-axis Effective Travel | 570mm |

| Sub-spindle Stroke (Z2 axis) | 610mm |

| Y-axis Effective Travel | ±50mm |

| X, Z1, Z2-axis Rapid Traverse | 20 (M/Min) |

| X,Y, Z-axis Servo Motor | 15/8/15NM |

| Drive Servo Motor | 17.5NM |

| Spindle Nose Type | A2-6 |

| Spindle Through-hole Diameter | Φ66 mm |

| Maximum Spindle Speed | 4500rpm |

| Spindle Motor Power | 11 Kw |

| Chuck and Rotary Cylinder Spec | 8 inches |

| Spindle Nose Type | A2-5 |

| Spindle Through-hole Diameter | Φ56 mm |

| Maximum Spindle Speed | 6000 rpm |

| Spindle Motor Power | 11 Kw |

| Chuck and Rotary Cylinder Spec | 6 inches |

| X, Z1, Z2-axis Positioning Accuracy | ±0.005mm |

| X, Z, Z2-axis Re-positioning Accuracy | ±0.003mm |

| Tool Holder Specification | □25*25 |

| Power Tool Turret Specifications | BMT55 |

| Boring Bar Specification | Φ32 |

| Turret | 12 Positions |

| Bed Structure Type | 30°Integral Slant Bed |

| Dimensions (L×W×H) | 2860*1830*1940 mm |

| Weight | 5000kg |

| CNC System | GSK | Control & Drive/Electrical |

| Servo Main Motor | GSK11Kw | Hydraulic System/Spindle/Tool Post |

| Sub-Spindle Servo Motor | GSK | Automatic Chip Conveyor |

| X, Z1, Z2-axis Servo Motors | GSK | Oil Bath Automatic Feeder |

| Y-axis Movable and Drive Servo Motor | GSK | Automatic Receiver |

| Spindle | Single-Part Automatic Feeder | |

| Spindle Bearings | Robotic Arm | |

| Sub-Spindle | Tool Post | |

| Sub-Spindle Bearings | Power System | |

| Ball Screw Bearings | NACHI | Manual HYdraulic Tailstock |

| Linear Guides |

X Axis: 35 Roller Z1 Axis: 35 Roller Z2 Axis: 35 Roller |

2 power tool holders at 0° and 2 at 90°, 2 boring tool holders, 2 radial tool holders, and 1 axial tool holder. |

| Ball Screws |

X Axis: 3210 Z1 Axis: 3210 Z2 Axis: 3210 |

|

| Hollow Rotary Cylinder | ||

| Hollow Hydraulic Chuck | ||

| Vertical Y-Axis Power Turret | Y80-12T-380Tool Holder | |

| Automatic Lubrication System | ||

| Cooling System | ||

| Heat Exchanger | ||

| Alarm Light | ||

| Electrical Components | ||

| Technical Manual |