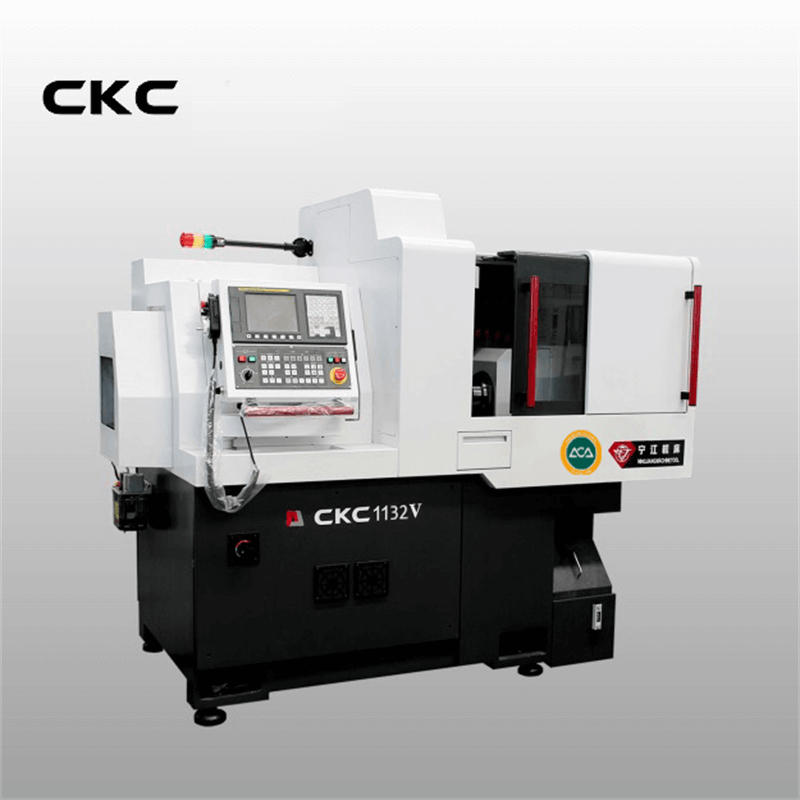

- FANUC 0i-TF Controller System

- Adopts 30m/min rapid traverse speed.

- Full-travel rotating center support.

- Rich tool layout with good expandability.

- Equipped with a rotatable control panel for better operability.

- Spindle&Sub-Spindle comes standard with C-axis functionality.

| Item | Specification |

| Maximum bar stock diameter | Φ32 mm |

| Maximum part length | 320 mm/chuck |

| 2.5D mm/chuck (without guide bushing) | |

| Maximum sub-spindle material length (front) | 150 mm |

| Maximum spindle speed | 6000 r/min |

| Spindle through-hole diameter | Φ39 mm |

| Spindle center height | 1100 mm |

| Main motor power | 5.5/7.5 kW |

| Maximum drilling diameter (front) | Φ12 mm |

| Maximum threading size (front) | M10 |

| External turning tools (lathe tools) | 6 tools |

| Front hole machining tools | 8 tools |

| Radial powered tools | 6 tools |

| Back-end machining tools | 13 tools (5 independent + 8 shared) |

| Turning toolholder size | □16×100~120 mm |

| Maximum radial powered tool speed | 4500 r/min |

| Radial powered tool motor power | 1.2 kW |

| Maximum drilling diameter (radial powered tool) | Φ8 mm |

| Maximum threading size (radial powered tool) | M6 |

| Maximum sub-spindle speed | 6000 r/min |

| Sub-spindle motor power | 3.7/5.5 kW |

| Maximum drilling diameter (back side) | Φ10 mm |

| Maximum threading size (back side) | M8 |

| Control method | Semi-closed loop |

| Detection components | Built-in servo motor encoder |

| Minimum unit for C1 and C2 axis setting | 0.001° |

| Minimum unit for X1, Y1, Z1, X2, Z2 axis setting | 0.001 mm |

| Rapid traverse speed for X1, Y1, Z1, X2, Z2 axes | 30 m/min |

| Effective travel for each axis | X1 ≥120 mm |

| Y1 ≥300 mm | |

| Z1 ≥300 mm | |

| X2 ≥350 mm | |

| Z2 ≥300 mm | |

| Servo motor power for X1, Y1, Z1, X2, Z2 axes | 1.2 kW |

| Repositioning accuracy | X1 axis: 0.002 mm |

| Y1 axis: 0.002 mm | |

| Z1 axis: 0.002 mm | |

| X2 axis: 0.002 mm | |

| Z2 axis: 0.002 mm | |

| Radial runout of spindle sleeve locating hole | 0.004 mm |

| Cooling motor power | 0.37 kW |

| Power input capacity | 15 kVA |

| Air supply pressure and flow rate | 0.5 MPa, 300 Nl/min (maximum) |

| Machine weight | ~4500 kg |

| Machine dimensions | 2700 mm x 1625 mm x 2100 mm |

| Standard Accessories | Optional Accessories | ||

| Protective cover | Material feeder | Automatically feeds materials; switches to the next bar when one is finished. | |

| Special tools | Flow detection device | Detects whether the cooling oil flow is normal. | |

| Base | Chip remover | Automatically collects waste chips during machining. | |

| Nameplate | Backside power tool drive device | Performs backside milling of parts. | |

| Column | Medium and high-pressure cooling device | Improves cooling efficiency and chip removal for difficult parts. Available in 70MPa or 100MPa options. | |

| Spindle | Oil mist purification device | Extracts oil mist from the machining area, usually paired with high-pressure devices. | |

| Tool rack | Cut-off tool breakage detection | Monitors the cut-off tool to prevent damage to other tools and the machine. | |

| Eight-axis end face drilling | Sub-spindle rear-end material discharge device | Collects long parts, customizable for lengths of 80 to 1000mm based on user needs. | |

| Pneumatic system | Backside side milling seat | Used for backside side milling. (Requires the backside power tool drive device.) | |

| Cooling system | Three-axis angle-adjustable front eccentric seat | For front eccentric hole, angled hole, and side milling. Installed on the radial power tool device. | |

| Lubrication system | Double-headed three-axis front eccentric seat | For front eccentric hole, angled hole, and side milling; the other head for back-axis machining. Requires two ER16 tool positions and removal of the four-axis fixed tool holder. | |

| Electrical system | Saw blade seat | Used for saw blade milling and slotting; installed on the radial power tool device, occupying two ER16 tool positions. | |

| Sub-spindle front-end material discharge | Backside saw blade seat | For backside saw blade milling and slotting. (Requires the backside power tool drive device.) | |

| Sub-spindle slide | Thread milling seat (whirling milling) | For thread machining of parts like worms or bone screws. Installed on the radial power tool device, occupying two ER16 tool positions. Requires removal of the four-axis fixed tool holder. | |

| Sub-spindle | Gear hobbing seat | For processing small module gears. Installed on the radial power tool device, occupying two ER16 tool positions. Requires removal of the four-axis fixed tool holder. | |

| Backside drilling | Three-axis front eccentric seat | For front axial eccentric hole and end face milling. Installed on the radial power tool device. | |

| Rotary center rest drive device | Milling angle seat | For machining external polygons on parts; custom tool discs based on part size. Installed on the radial power tool device. | |

| Rotary center rest | Three-hole drilling seat | Expands the number of tool positions for hole machining; installed on the radial power tool device, often used with five-axis radial power tool drive device. | |

| Powered tool drive device | Back machining straight-shank rotary tool seat | For axial milling, eccentric hole drilling, and tapping on the back-axis. Requires the backside power tool drive device. | |

| Powered tool | Back machining drilling seat | For axial hole machining on the back side. Requires the backside power tool drive device. | |

| Machine lighting | Backside rotary broaching seat | For backside axial hexagonal hole machining. | |

| Machine three-color alarm light | |||

| Part transfer device | |||

| Internal cooling device for the main and sub-spindles | |||

| Spindle chuck | |||

| Center rest chuck | |||

| End face machining chuck (front and back) | |||

| Powered tool chuck | |||

| Sub-Spindle Chuck |